This is a good car - I like driivng it. Especially now that it

is all coming together.Common problem #1. Suspension struts leak oil,

boots have split

No springs, no sway bars, no airbags, no regular shocks - just computer controlled

hydraulic active suspension struts.Years of weeping oil had attracted dust and dirt

coating the strut. Instant fail for any road worthy test. Typically the boot had started

to split. Time to yank them, new seals, new guides, new boots, cut open the accumulators,

install new seals, re-gass with nitrogen to the correct pressure and they will be as good

as new.

I bought the complete set of parts to refurbish the top half of the struts. As usual

ask for James Sloane at Castle Hill Toyota. http://www.chtoyota.com.au/chtparts.html

Complete kit comes in at around $1200. Fluid is extra - I always like to extra fluid on

hand.

I used to pull the whole strut out. Now I just unsrew it in half and remove the

accumulator and fit all the new parts with the top half still in the car. Saves me time, a

vice and I can do everything I want with the strut held firmly. It's so much better. No

more mucking around removing the suspension arm or undoing hydraulic lines. In car

accumulator removal is the way to go for me (the rears I have to loosen the top bolts to

angle the strut to get the accumulator off).

Accumulators I also get from Peter Taplin. He is continually improving the

re-manufacturing process. These ones have new seals and R-134 valves. Although these

valves have been upgraded to stainless schrader valves, I do like the ease of push connect

fittings to recharge with nitrogen. All four accumulators have been replaced.

600 psi Nitrogen regulators retail for $440 at BOC. I got myself this Smith regulator

from EBAY US for $70 US plus postage. I then bought a $40 type 51 nitrogen fitting from

BOC so it would connect to an Australian nitrogen bottle. The bottle I hired from an

commercial airconditioning supply place- $40 for the bottle plus a monthly hire

rental of about $8 a month. I just set the regulator to the pressure I want and let it

equalise with the accumulator.

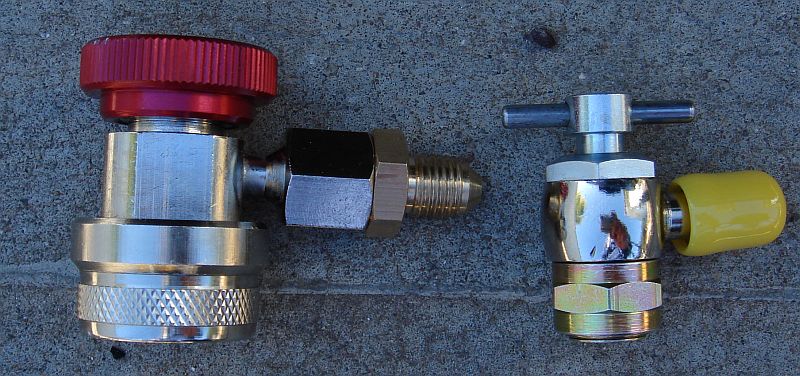

R134 fitting on the left - quick and easy push on fitting, twist the red knob to let

the gas in. On the right is the rare schrader valve fitting - it screws on the valve and

the T-handle turns to let the gas in.

The most important thing when gassing the accumulators on the car is to open the bleed

valve first. This makes the suspension sink to the floor so I always jack up the car

first. With the bleed valve open the floating piston can rise to the top of the

accumulator to let nitrogen in the bottom. If the bleed valve isn't open, oil is trapped

on top of the piston, it can't move and there is no space below to pressurise nitrogen.

With the bleed valve open, big car stands holding the car up, the nitrogen

regulator set to 218 psi for the rear accumulators (254 psi for the fronts), I push on the

fitting, turn the red knob to open hear that short satisfying whoosh as gas pressures up.

Then I close the knob, pull off, do the other side then up to the front. Don't even need

to take the wheels off to regas the accumulators. This is so cool. The push on fitting and

yellow hose will stay with this car so that the new ower can regas where and when they

want. The brake booster accumulator has the same fiting too.

Common problem #2 - after market rims with no hub-centric rings.

This Soarer had non-genuine rims fitted. While most after market rims come with a large

centre bore of 73mm. The Soarer has a 60.1 mm hub. Getting hub centric rings to go

from 60.1 to 73mm is a doddle - they are available everywhere for just $20 for a set of

four.

These rims have a 70.6 mm hub. Getting rings that go from 60.1mm to 70.6 is hard - they

have to be custom made. So fitting these rims to a Soarer (they have the same 5 x 114.3mm

stud pattern) means getting custom spigot rings made. I got the above rings made for $60

delivered by express post to Adelaide from Sydney.

Tempe Tyres - Sam was the guy I talked to. 02 9573 1010

860 Princess Highway, Tempe NSW 2044

Now that the rings are inserted into the rims- they will safely bolt up to the

Soarer without putting any shear stress on the studs. All after market rims must have

these rings installed to prevent stud failure. Every single car leaves the factory with

neat fitting hubs and rims. With no spigot rings too much shear stress is put on the studs

- failure can result: http://www.planetsoarer.com/offset/studs.htm

Common problem #3 - leather gets old looking.

I installed a Soarer black upgrade pack. Coloured wheels are a bit old fashioned so I

went for black leather upgrade for the shifter, handbrake grip, handbrake cover and

steering wheel. I then had the plastic buttons, horn pad and steering wheel column covers

recoloured to match.

For this Soarer wheel I went the optional sport grip perforated leather option with

contrasting white baseball stitch. My leather guy does all the HSV factory leather and had

a pile of wheels ready to go - they looked good so I just asked for the same.

Common problem #4 - due for a cambelt/ waterpump service

The water pump was weeping and needed to be replaced. With the labour involved it made

sense to replace everything with new stuff. Timing belt, bearings, water pump, caps and

rotors, plugs and thermostat and serpentine belts to be replaced.

I went for new genuine Toyota pump and belt, BOSCH caps and rotors, KOYO tensioner and

idler bearings and generic serpentine belts. There is a bearing not shown for the pump

idler.

Getting there. This is only my 2nd timing belt install on a 32- it's much easier

second time around. I always triple check that the timing belt is lined up with the two

cams perfectly - I have heard to many bad stories of it being out buy just one tooth.

Nothing breaks but the car has no power and won't rev if out by one tooth. That's a

re-manufactured air-conditioning compressor as well.

The great big plate across the front of the engine on the 32 is always a bit of a

struggle. I find it gets caught up on the rubber power steering hoses. I'm getting better

at it but it ain't much fun. Apparently it's easier on every other 1UZ-FE - but the

Actives are all different. Some workshops will quote an extra 5 hours labour doing an

Active belt over a regular Soarer, Celsior etc!.

Common problem #5 - hinges stuffed

The door hinge was worn - so I unplugged the loom from the foot well, supported the

door with a trolley jack and wood, and changed it over. The loom goes through the hinge so

I thought it would be a bit easier to unplug it from the foot well rather than remove the

whole loom from the door. Better than new hinges are now available from Daryl

http://www.planetsoarer.com/hinges/index.htm

Common problem #6 - Boot struts failure.

I bought some of those $48 ebay Soarer boot gas struts. This 1991 model Soarer needed

the ones with the nut and bolt end. There are two types I think. I found them hard to

install. I ended up removing the clip that holds the bolt, and then pressing the strut as

hard as I could to get it on.

Common problem #7 - Door window regulator failed

Another common Soarer problem- the plastic bit on the window regulator had broke. It is

expensive at $240 retail to replace. New one on the left.

The EMV screen talks to the built in GPS and insists I'm driving in Japan.

Common problem #8 - Transmission shifting from 1st to 3rd - solenoids playing up.

Now and again the trans would short shift 2nd gear and go to third gear. This made the

car sluggish. It had happened to my own Soarer years ago and it probably was the solenoids

in the trans playing up. I wanted Michael at MV Automatics to put a pair of new solenoids

in the trans and give it a service. Before I gave the car to Michael I flushed the trans

with copius amounts of fluid!

For the V8 I always use Toyota T-IV trans fluid. http://planetsoarer.com/autotrans/autotrans.htm

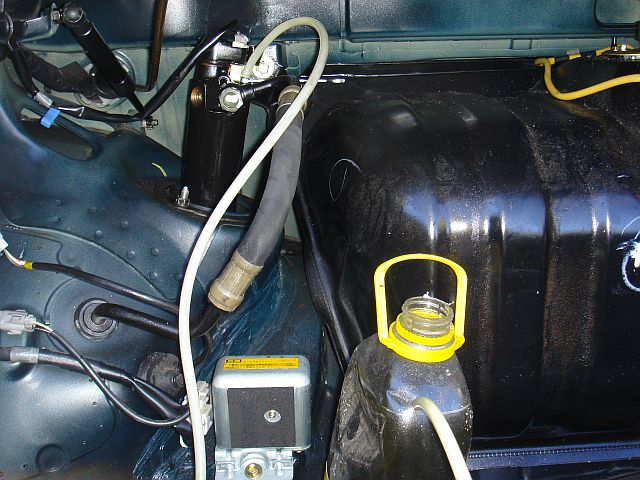

To flush the trans I connect a rubber hose to the trans cooler line that exits the

radiator on the battery side of the car. Then I start the car for a few seconds, watch the

fluid pump into the bottle, turn off refill with new fluid and do it all again. This pumps

new fluid through the trans, the torque convertor, the cooler and out into the bottle.

When the bottle starts to fill with new looking clear red fluid I stop and refill. Usually

takes me around 20 litres to do the job. Correct fluid level is with the car running in

park.

Here is Michael at MV Automatics with the Soarer. I leave it with him all day and catch

the train to work from Blackwood to Adelaide. Michael serviced the trans and replaced the

solenoids with new ones. The trans is fabulous now.

Common problem #9 - Brake discs, fluid bleed and booster accumulator.

Front discs had plenty of meat and pad left so a light skim for them

As usual the rear discs where marginal so new ones for the back. I like Castrol

Response4 - easy to get, high boiling point and affordable.

I always like to remind myself before putting the disc on which way to adjust the

handbrake shoes with the screwdriver.

Handle down and the handbrake gets tight - I like to get it so I just hear it start to

touch the hub.

The rear pads had lots of life left so used my special pad pusher to push the piston

back. I bleed the whole system with new brake fluid. Bleeding the TRC booster as per the

manual always gives me a nice high firm pedal. http://planetsoarer.com/mediumbrakes/masterbleed.htm

I removed the accumulator on the master cylinder with the key off and having pressed

the brake pedal 40 odd times to release any pressure.

The accumulator at rest has about 1200 psi of nitrogen above a floating piston when

new. I got a Peter Taplin recond job with new seals and a valve on top to top up with

nitrogen if needed.

I made a bit of a too up to remove the accumulator from the master cylinder. Next time

I'll just use a pipe wrench - it scratches it a little bit but I don't think it matters. I

didn't bother unscrewing the accumulator into top and bottom bits- the bottom lip is

rolled over the thread making to stop it coming apart. Peter Taplin uses a lathe to remove

the lip before rebuilding them. New price is around the $400 to $600 mark I hear.

Now the brakes are terrific.

Common problem #10 - Cooling system

Seems like the most common cause of engine failure is top radiator tank failure! I have

seen some disasterous top tank failures. Nowadays it is easy to get any radiator repair

shop to replace the top tank. My radiator mate reckons the top tank should be replaced

regularly like any serviceable item rather than waiting for it to fail and risk destroying

the engine due to overheating. Another thing he showed me was scrape marks on the

thermostat means it should be replaced too.

Apparently these marks means it's time for a new thermostat. So I popped on in with

fresh coolant.

Common problem #11 - Spark plugs

Genuine platimim plugs should be replaced every 100 000 km. I got these Iridium plugs

because that was what my brother provided me- it wasn't a special preference or

anything. Biggest cause of misfiring I reckon is water in the sparkplug holes.

Biggest cause of plug lead failure is changing the plugs and pulling a lead wrong and

breaking it. I use a pair of pliers on the plug cap where the grip is - I never touch the

actual wire itself - too easy to break and pull out of the cap etc. http://planetsoarer.com/penski/ThePenskiFile.html

|