|

Wheels falling off and broken studs |

by Peter Scott

My mate Gazza, recently had an "off" at the race track :( - but he's ok.

The Before shot - note wheel is still on !

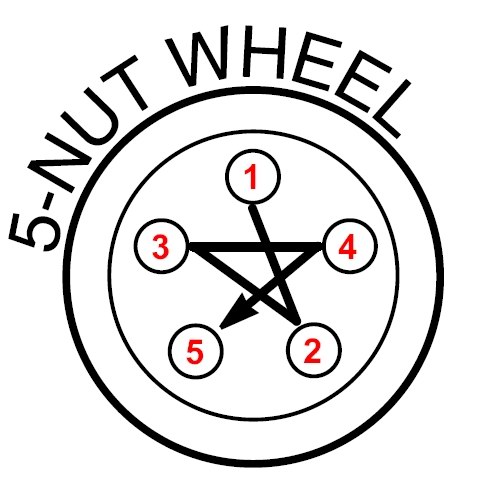

Gazza scored these 18 inch beauties for only $880 for all four - bargain! Multi fit inexpensive wheels are a bit heavy, relatively soft, come with 10 holes for studs (fit more cars this way) and have a large 70 mm centre hole (fit more cars see). Five of the wheel stud holes are 114.3mm and fit the Soarer - the other 5 holes are for other cars - this is called "multi-fit". "Multi-fit" is your guarantee that the wheels were not designed specifically for your car.

The Soarer, Toyota and Lexus cars come with a 60.06mm centre spigot to support the wheel - a 70 mm centre hole is big enough to go on any car - it's a "multi-fit" centre hole that slops around on the studs putting tremendous shear stress on the studs.

The wheels were fitted without a centre spigot (or is it spiggot?) ring to the wheel.

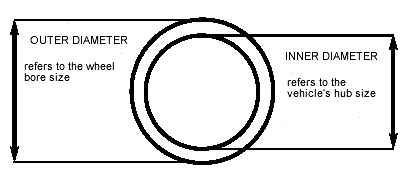

Motor vehicle

manufacturers use a central location collar on the stub axle hub in order to accurately

locate the wheel. The wheel collar diameter varies, depending on the make of vehicle.

Many replacement allow wheel manufacturers use an adapter (spigot ring) to vary the

diameter of the locating hole. In this way, a particular wheel can, by changing the spigot

ring, be used on a variety of vehicles.

The spigot is the bit in the centre of the hub that you rest the inside centre of the wheel on whilst aligning the studs and screwing back the wheel nuts. On generic after market wheels, the spigot hole inside the wheels is a lot bigger than the spigot on the car. So what you need to do in this case is fit spigot locating rings. These are just rings of aluminum or hard plastic, that fit over the spigot on your car and then have a proper fit with the spigot hole on the wheel. If you don't have the spigot taking all the weight of the car, chances are you'll break one or more studs when you drive the car hard or have to brake hard. Remember the wheel nuts are simply there to hold the wheel on, NOT support the weight of the car. Also, as there is nothing to centre the wheel, you'll notice the wheels go in and out of balance because as you drive around, they'll move around on the hub.

More information on offset and spigot rings see the offset page.

Bingo! Three broken studs. The wheel vibrates, wobbles and the other studs work loose once some studs are sheared through. See the rusty ring around the middle? That is roughly where the spigot ring should go supporting the wheel on the hub. The studs cannot support the wheel force - they can only hold the wheel on the hub. Studs are one and half times weaker in shear than tension. Once a stud shears it places more load on the other studs. Usually the wheel wobbles nuts off before all the studs shear.

Once the wheel comes off first thing it does is wreck the guard, ouch!

Carnage!! What a mess.

With the wheel going off in the distance the car hits the deck and the brake disk grinds into the ground. When the disk hit the ground at high speed on the track it cracked as it's not designed as a wheel. Garry replaced both disks, and all studs.

Gazza is tough as nails and nothing stops him. He fixed the car on site with a pair of pliers, drove 850 km home from the track and fitted a new black guard! So thanks Gazza for the invaluable lesson. Something I'll never forget!

Quote:

First lap I was going

hard, those Pzero Slicks stuck to the ground, coming around for lap two. flew out of turn

2 (Honda) perfect turn into Siberia , just coming out of apex, right foot to the floor,

then just for a split second in the corner of my eye, it looks like a tyre flying off into

the gravel trap ! what the hang!

Crash !, Right side of

car dips down and slides along the track onto the grass and goes parallel to the gravel

trap, holy cow I've lost a tyre ( I thought), comes to a stop .

Manages to open door, then has a look at what's happened, Holy Molly I haven't just lost a

tyre, the whole wheel has disappeared as well!

I go and get my tyre, slashed to bits, no good now.

Then realise that I've sheared nearly all my hub bolts off!

It's only later on reflection I realised why!) Ah duh!

Tow truck comes out and drags the beast backwards onto the tow truck.

By the way let this be a warning to you guys who have an FMIC fitted and decide to get rid

of your under tray, DON'T!, my car just slide over the grass, because I had my FMIC fitted

with the under trays still in place, if I had not, then the whole of the front FMIC etc

would have got damaged, as it happened everything‚€™s fine apart from my right

Guard and rotor.

Truck took car back to where I had my gear, and then set about fixing (best I could) the

damage, knocked out broken studs, and took two from passenger front hub.

Mark was there all the time giving me moral support!( cheers mate!)

And waited till I was ready to go home, he followed me till I got to Juzza's road at

Cranbourne.

Popped in had a quick cup off tea, (juzza thought I was staying the night!)

Should have seen his face when I told him I was going home now, as I had to be at work

Monday morning 5.30am!

So off I went home staying a steady 100ks all the way home.

Managed to pick up a Right hand Guard (BLACK!) on way home from work Monday, picked up my

new Hub Bolts today, and my new rotors wed!

AND! Getting my Spigot Rings for my 18" rims on Friday.

Decided to change all my Hub Bolts as best to be safe than sorry, don't fancy having that

happen again thanks very much!

Check out this list of broken stud problems:

N.O.S. + Drifting + 2 extra passengers=

Wheel Fell off - Lug Bolts Snapped off

Spigot rings are cheap at $10 a set. Ring Gary Boddis Ph. (07) 5443 6055 The Tyre Factory Maroochydore for a set. They are also called hub centric rings.Hub centric rings are usually made of high quality poly carbon or an alloy metal. The ads for the poly carbon say things like " The advantage of polycarbonate hub rings over the metal ones is that metal rings tend to corrode very easily for a small amount of moisture and thus makes it hard to take wheels off your car. Polycarbonate rings never have this problem. " Naturally enough the metal ring guys say " Do not be fooled by the so-called Poly Carbon rings. Metal rings are much better quality than plastic/poly carbon rings and are made to a more exact, closer tolerance for a proper fitment. They won't crack, melt or break over time like plastic rings do."

A quick ebay.com search finds heaps of hub centric rings.

O.D. 73.00MM/I.D. 60.06MM Hub Centric Rings are

commonly needed for the Soarer/Celsior.

Plastic rings:

Metal rings:

"Hub centric rings" are a common buy on ebay.com. I have the alloy type rings on my BBS forged circuit rims with cone nuts.

Correct torque for a stock wheel nut on a stock Toyota/Lexus rims is 103Nm (76 ft.lbf).

Colin Kirkpatrick (esteemed UZZ32 owner) from T&E Tools as

the following torque wrench for a group

buy @$85 dollars plus postage. Contact Colin at colink@bigpond.net.au

The Trade price for this wrench is $165 dollars.

Some things you show know when using a torque Wrench!

1. Once you have finished using it, you should set it the lowest scale reading to take the

load off the internals parts. Plus store it in the blow mold case for protection.

2. Place your hand on the handle only as this does effect the torque reading.

3. Once the torque wrench clicks at the set reading, stop and release the pressure other

wise you will over torque.

It is often said that 103Nm (76 ft.lbf) is on the low side for wheel nuts. This isn't because the Toyota/Lexus has special studs - it's because they have very efficient nuts. The clamping surface of the nut applies 100% of it's force to the tension of the studs. Old fashioned cone nuts only apply a percentage of the clamping force to the stud - the rest of the force is applied to the horizontally to the wheel - cone nuts try to "spread" the hole.

On the left is the old fashioned cone nut - popular with multifit aftermarket wheels. On the right is a genuine Toyota/Lexus nut with a square clamping face. Since most aftermarket rims come with a large centre hole to cover all types of cars - they are provided with cone nuts to locate the wheel.

Genuine Toyota wheels have a flat face for the nut to clamp down on. And of course the perfect centre hole for the 60.06mm hub of the Soarer/Celsior.

Cone type nuts (120Nm torque needed) put tension on the stud and press the hole in the wheel outwards. Toyota nuts (only 103 Nm torque needed) with the square shoulder only put tension on the stud - no "spreading" of the hole. Toyota nuts don't need to be as tight as cone type nuts for to achieve the same tension on the stud. Threads, nuts and wheel holes must be spotless to achieve correct friction levels. No traces of rust, dirt, crud or paint must be there. I clean mine with WD-40, wire brush and a clean rag. Toyota nuts should be cleaned between the captive washer and the bolt head as well.

The stud is stretched by the action of the wheel nut when it is tightened. This stretch in the stud is what generates clamp load in the stud. The wheel is clamped to the hub by the force of the stud trying to return to its original (shorter) length. When a torque value is applied to the wheel nut, that represents the resistance that is experienced to turning the nut. This should be related to the lengthening of the stud (and the subsequent result: clamping force). By measuring only the torque the proper clamp load may not be correct due to: high friction at the lug nut/wheel surfaces from excessive paint, contamination, foreign materials on the surfaces, and uneven, galled, or scarred surfaces; or friction at the lug nut/stud interface from cross-threaded nuts, excessive paint, contamination, or foreign materials on the surfaces.