|

Estimating Boost and Eaton Pulley Change |

by Peter Scott

Estimating boost and power from different size pulleys on the Eaton M90 & M112 superchargers on the 1UZ-FE. A look at Pulley suppliers and specialised pulley pullers!

There are formulas for estimating boost (described later) - here is a summary. Red colour is danger colour, boost greater than 6 psi.

Blower Pulley (inches) |

Blower rpm at redline (6250) |

M112

estimated |

M90

estimated |

3.8 |

9046 |

4.60 | 0.95 |

3.7 |

9291 |

5.11 | 1.35 |

3.6 |

9549 |

5.64 | 1.78 |

3.5 |

9821 |

6.20 | 2.23 |

3.4 |

10110 |

6.80 | 2.71 |

3.3 |

10417 |

7.43 | 3.22 |

3.2 |

10742 |

8.10 | 3.76 |

3.1 |

11089 |

8.81 | 4.33 |

3.0 |

11458 |

9.58 | 4.94 |

2.9 |

11853 |

10.39 | 5.60 |

2.8 |

12277 |

11.26 | 6.30 |

2.7 |

12731 |

12.20 | 7.05 |

2.6 |

13221 |

13.21 | 7.86 |

2.5 |

13750 |

14.30 | 8.74 |

2.4 |

14323 |

15.48 | 9.69 |

Estimating power is often quoted as just (14.7 +boost)divided by 14.7, times stock power.

psi boost |

estimated flywheel kW |

estimated |

no boost stock n/a |

190 |

255 |

1 |

203 |

272 |

2 |

216 |

289 |

3 |

229 |

307 |

4 |

242 |

324 |

5 |

255 |

341 |

6 |

268 |

359 |

7 |

280 |

376 |

8 |

293 |

393 |

9 |

306 |

411 |

10 |

319 |

428 |

11 |

332 |

445 |

12 |

345 |

463 |

13 |

358 |

480 |

14 |

371 |

497 |

15 |

384 |

515 |

Several supercharged 1UZ-FE's have ended up with 170 rwkW (225 rwhp) from the 5-6 psi boost mark, non-intercooled. A healthy 1UZ-FE is often quoted at 140 rwkW (188 rwhp). The twin intercooled 4.0L Jaguar V8 with a M112 is rated at 278 kW at 12 psi boost. Allowing for a 23% drivetrain loss that might put it at the 210 kW at the wheels.So projecting these figures I estimated power at the wheels. Not exact, but I'll use it as a guide.

psi boost |

Empirical |

Empirical |

0 |

140 |

188 |

1 |

144 |

193 |

2 |

154 |

206 |

3 |

160 |

214 |

4 |

168 |

225 |

5 |

176 |

236 |

6 |

180 |

241 |

7 |

185 |

248 |

8 |

192 |

257 |

9 |

195 |

261 |

10 |

203 |

272 |

11 |

210 |

281 |

12 |

214 |

287 |

13 |

223 |

299 |

14 |

230 |

308 |

15 |

238 |

319 |

The 1UZ-FE has a 5.5 inch crank drive pulley. Boost is directly related to the size of the driven pulley on the supercharger.

Boost (psi) = (PR x 14.7 x V / C/2 ) - 14.7 - I

PR is pulley ratio, crank pulley diameter divided by drive pulley diameter. e.g. The stock Jaguar M112 pulley is 3 inches in diameter, therefore 5.5/3= 1.83

14.7 is the pressure of the air we live in, we don't live in a vacuum, we live in 14.7 psi.

V is the volume of the Eaton blower for one rotation. The M90 is 90 cubic inches or 1475 cc. The Eaton M112 is 112 cubic inches or 1835cc. Turn it once and it pumps out 1.835 litres of air.

C is capacity of the engine in cc : 4000 cc for the 1UZ-FE. The C/2 is C divided by 2 - because for one rotation, a four stroke engine is only half way through a complete cycle. When the piston is up the top and starts going down, air and fuel go in, then it gets to the bottom and goes back up and compresses the mixture. That's one rotation. Then the spark plug ignites the mixture and it starts to go down again, it gets to the bottom and then goes back up again pushing the burnt mixture out the exhaust valve and returns to the top to start over again. That's two rotations.

I (capital "i") is an allowance for boost lost due to valve overlap. All engines have valve overlap; the intake valve opens before the exhaust valve closes - the incoming fresh air and fuel pushes out the last of the burnt exhaust gases. The 1UZ-FE has a small overlap of only 9 degrees. Nissan's RB26DETT has 14 degrees, Subaru EJ20 has 16 degrees and the turbo EJ20 has 14 degrees. The allowance is quoted as 5% boost lost for every 10 degrees of overlap. So for the 1UZ-FE at 6 psi boost, perhaps boost loss is 0.05 x 9/10 x 6psi = 0.27 psi lost - it's not much.

Stock Eaton M112 pulleys are 8 ribs, and available as 3.2, 3.1, 3.0, 2.9, 2.8 inch diameter. Can't change the pulley on the stock Jag fitment, but because of a different pulley it is possible on the 2003 Mustang and Lightening truck. Might be able to fit the 6 rib M90 pulley to the M112 which would mean more sizes available. The M112 needs a wider 8 rib belt to avoid slippage - it takes more power to drive it compared to the M90. High boost on the M112 with a skinny 6 rib belt may invite slippage.

| Eaton M112 on 1UZ-FE estimated boost | |||||

Blower Pulley (inches) |

Crank Pulley (inches) |

ratio |

Boost (psi) |

I (overlap loss,psi) |

Est. Boost (psi) |

3.8 |

5.5 |

1.45 |

4.82 |

0.22 |

4.60 |

3.7 |

5.5 |

1.49 |

5.35 |

0.24 |

5.11 |

3.6 |

5.5 |

1.53 |

5.91 |

0.27 |

5.64 |

3.5 |

5.5 |

1.57 |

6.49 |

0.29 |

6.20 |

3.4 |

5.5 |

1.62 |

7.12 |

0.32 |

6.80 |

3.3 |

5.5 |

1.67 |

7.78 |

0.35 |

7.43 |

3.2 |

5.5 |

1.72 |

8.48 |

0.38 |

8.10 |

3.1 |

5.5 |

1.77 |

9.23 |

0.42 |

8.81 |

3.0 |

5.5 |

1.83 |

10.03 |

0.45 |

9.58 |

2.9 |

5.5 |

1.90 |

10.88 |

0.49 |

10.39 |

2.8 |

5.5 |

1.96 |

11.79 |

0.53 |

11.26 |

2.7 |

5.5 |

2.04 |

12.77 |

0.57 |

12.20 |

2.6 |

5.5 |

2.12 |

13.83 |

0.62 |

13.21 |

2.5 |

5.5 |

2.20 |

14.97 |

0.67 |

14.30 |

2.4 |

5.5 |

2.29 |

16.21 |

0.73 |

15.48 |

Eaton M90 pulleys are 6 rib and are available in 2.4" 2.5" 2.6"

2.7" 2.8" 2.9" 3.0" 3.1"

3.2" 3.3" 3.4" 3.5" & 3.8" diameters.

Eaton M90 on 1UZ-FE estimated boost |

|||||

Blower Pulley |

Crank Pulley |

ratio |

Boost (psi) |

I (overlap loss) |

Est. Boost (psi) |

3.8 |

5.5 |

1.45 |

0.99 |

0.04 |

0.95 |

3.7 |

5.5 |

1.49 |

1.42 |

0.06 |

1.35 |

3.6 |

5.5 |

1.53 |

1.86 |

0.08 |

1.78 |

3.5 |

5.5 |

1.57 |

2.34 |

0.11 |

2.23 |

3.4 |

5.5 |

1.62 |

2.84 |

0.13 |

2.71 |

3.3 |

5.5 |

1.67 |

3.37 |

0.15 |

3.22 |

3.2 |

5.5 |

1.72 |

3.93 |

0.18 |

3.76 |

3.1 |

5.5 |

1.77 |

4.53 |

0.20 |

4.33 |

3.0 |

5.5 |

1.83 |

5.18 |

0.23 |

4.94 |

2.9 |

5.5 |

1.90 |

5.86 |

0.26 |

5.60 |

2.8 |

5.5 |

1.96 |

6.60 |

0.30 |

6.30 |

2.7 |

5.5 |

2.04 |

7.38 |

0.33 |

7.05 |

2.6 |

5.5 |

2.12 |

8.23 |

0.37 |

7.86 |

2.5 |

5.5 |

2.20 |

9.15 |

0.41 |

8.74 |

2.4 |

5.5 |

2.29 |

10.14 |

0.46 |

9.69 |

Graphs for Eaton blowers are readily available - these graphs are from capa.com.au

Notice the bigger M112 blower is narrower and longer.

The Jaguar has a custom casting for it's M112 - only the rotors etc are the same. The Jaguar doesn't use an internal bypass - it has a dual bypass for each intercooler.

For 5 psi the M90 requires 20 hp at 10 000 rpm, and increases the air temp by 95

degrees F. The M112 for the same 5 psi requires 25 hp and heats the air an extra 115

degrees. The M90 does a better job - that's why it's on the RUSH blower. The M90 also

builds boost quicker.

M112 Graphs

Ok so now I've estimated what size pulley will give me what sort of boost and and perhaps an indication of what sort of power. Next trick is to figure out how to remove the Eaton pulley and stick another one on. Why is it we often buy a Soarer then find out all about them, or try to remove a pulley and then find out how to remove them properly? I gave it a go with a 3 jaw puller and nothing but tears - only then do I decide to check the net and low and behold there are the answers - and it ain't no three jaw puller!

The pulley can't be changed for a smaller one on the factory Jag supercharger. The pulley is wide, and it goes over the aluminium snout of the supercharger - designed from the factory to stop tampering. Eaton also press fit the pulley with a 20 ton press. The Biggest meanest 3 jaw pulley won't touch it - shaft damage, pulley damage - it's all been done.

Capa offer a complete snout change over with a smaller pulley the only way they

recommend because it's that difficult to change the pulley. http://www.capa.com.au/eaton.htm They

do have one for the M112 - but it's a different casting to the Jag one and won't have cast

bolt holes needed to mount the blower.

Commodore V6 M90 Supercharged VT-VY Snout Assembly - 3.4" (8psi) or 3.6" (9psi)

$695 for all this, $495 for custom chip and saddle -

$700 labour to fit.

$695 for all this, $495 for custom chip and saddle -

$700 labour to fit.

http://www.v6supercharged.com.au/ offer a special Eaton specific pulley puller for rent combined with a quick change replacement pulley. For the same price as the CAPA replacement snout, you get a pulley and tool hire. Since there are no labour costs it can work out cheaper.

$695

Complete Pulley kit comes with:

* 1 x 10 psi Pulley

* 1 x Modular Hub

* 1 x Shorter Belt

* 1 x Pulley Removal

* Re-installation Tool Rental Instructions

Previously, this technology and know-how was unavailable due to the manufacturer, Eaton,

using a 20 tonne press to fix the pulley to the shaft. This was to deter aftermarket

workshops and prying mechanics from removing the original pulley from the shaft and

swapping it for a smaller one.

Many have tried to remove the original pulley with disastrous results, such as bending or

breaking the pulley, damaging the bearing, and/or scouring the shaft. Let us for-warn you

that no aftermarket available puller kit, even the most heavy duty claw type ones, will

even come close to pulling the pulley off the shaft without severely distorting the

pulley. If attempted and the pulley becomes bent or deformed you wont be able to just put

the belt on and go again. It will then cost a lot of money to repair the damage.

At Forced Induction Technologies, we have devised a method using specially engineered

tooling, which allows you to remove the existing pulley from the shaft whilst the

supercharger is still in place. That's right, there is:

* NO NEED TO REMOVE THE SUPERCHARGER

* NO NEED TO CHANGE OIL

* NO GASKETS REQUIRED

* CAN BE DONE IN 1 HOUR

And if you ever wanted to return it back to standard it's easily possible. Best of all it

comes with very complete and concise instructions for DIY installations, or if you prefer,

any general mechanic will have it sorted within 1 hour! Forced Induction Technologies have

5 common sized pulleys in stock to produce up to 10, 11, 12, 13 or 14psi (note this

is for V6 GM motors). Pulleys can be swapped over in 10 Minutes due to the modular hub

and interchangeable pulley design. This is great for wanting to swap to a smaller pulley

for quarter mile racing, and then running the regular one for street use and fuel economy.

In the USA the same sort of interchangeable pulley can be bought for $155 US. This is for the GM Series II & III. I don't know if the shaft size is the same as the M112 - I hope so - this is the one I would like to fit - one for street use - one for drags and dyno days perhaps?

Pulley Boys

tm QwikchangetmCurrently available in the following pulley sizes:

2.4" 2.5" 2.6" 2.7" 2.8" 2.9" 3.0" 3.1" 3.2"

3.3" 3.4" 3.5" & 3.8"!

$155US, extra pulleys are $70US

$155US, extra pulleys are $70US

Featuring a PH 15-5 stainless steel hub with a 6061 T651 cold drawn aluminum pulley that

is clear anodized and 18-8 stainless steel hardware.

They also have press fit steel pulleys for the M112 and M90. The Ford 03 Cobra and Lightening have the M112.

This is the fancy custom made puller for the Eaton pulley: $129 US - pulls off the old pulley and pushes on the new pulley. Looks like they have slightly different ones for different installations.

http://www.pulleyboys.com/gmm90pt.html

m112 and M90 tool both cost $129 US

http://www.pulleyboys.com/m112pt.html

Cobra intercooled M112 puller

Remove configuration

Install configuration

Keene Bell always have nice stuff - their pulley puller tool looks a treat as well. Advice is given against getting an aluminium pulley.

http://www.kennebell.net/accessories/accessories-home.htm

BILLET PULLEY PULLER (EATON SUPERCHARGER) - There are 3 ways to change pulleys on an Eaton. The most expensive and time consuming is to replace the entire drive assembly with a new one and a smaller pulley. So if you're alternating 3 pulleys, you would need 3 new expensive drive assemblies. Why buy a drive assembly just to get a pulley? The second method utilizes old style pullers that usually bend and ruin the pulley the first time. The new lightweight Kenne Bell Billet Aluminum Pulley Puller is the easiest and most economical way of removing pulleys from the stock Eaton drive. It doesn't distort and ruin your pulley and you don't have to buy new drives for each pulley change. A pulley can be removed or replaced in 5 minutes with this tool. Great for alternating "street" and "race" pulleys. Note: We DO NOT recommend aluminum supercharger pulleys because of the high belt speed and resultant wear.

• LIGHTWEIGHT

• EASY TO OPERATE

• REMOVES & INSTALLS EATON PULLEYS

Part# F2500

STEEL SUPERCHARGER PULLEYS - No one offers more steel pulleys for the Kenne Bell Twin

Screw and Eaton Roots superchargers - because pulleys and superchargers are our business

and not a sideline. Supercharger/driven pulleys are only 1/3 the diameter of crank/drive

pulleys and therefore spin at approximately 3 times the speed of the crank - 750 ft/sec.

This equates to over an 1/8 mile per second! That's a lot of heat and friction. Could that

be why the OEM's use steel supercharger pulleys exclusively? It's precisely why Kenne Bell

has never used the softer aluminum supercharger pulleys with serpentine belts - and never

will. We use only durable long life high grade plated steel for both Kenne Bell and Eaton

superchargers. It's common practice to switch pulleys to vary boost levels for street,

weekend racing etc. Kenne Bell Steel Pulleys can be quickly and easily replaced with one

bolt using the Kenne Bell Pulley Wrench (Twin Screw) or the Kenne Bell Billet Pulley

Puller (Eaton). Stock Eaton pulleys are pressed on, constructed of relatively soft high

lead material and are therefore easily bent by "old style" pullers when removed.

Reinstallation is also difficult, requiring a press if a good installation tool is not

available. Kenne Bell Steel Pulleys are virtually indestructible. Big selection. Precision

machined steel and plated for corrosion resistance.

• LONGER BELT LIFE

• DURABLE STEEL

• LESS WEAR

Part# F2000

8 Rib Pulleys EATON (Cobra & Lightning)

3", *2.75" (Kenne Bell F2500 Pulley Puller recommended)

*2.75" is smallest pulley that can be used on the Eaton.

8 Rib Pulleys KENNE BELL (Cobra)

4", 3-3/4", 3-1/2", 3-1/4", 3", 2-3/4", 2-1/2" (Kenne

Bell SC3140 Pulley Wrench required)

8 Rib Pulleys KENNE BELL (Lightning)

3-1/4", 3", 2-3/4", 2-1/2" (Kenne Bell SC3140 Pulley Wrench required)

Note: Boost pressures are to be used as a guide and may vary

We don't recommend a

larger than stock crank pulley on the Cobra as boost drop off at 6000 in the high winding

Cobra is substantial with a 2.75" pulley (2.72 ratio ). Note

2.72 ratio - that's huge!

**Boost pressures will vary with inlet restriction. For comparison, all tests were

conducted with stock inlet systems. For example: with a 2.75" pulley, '03 Cobra boost

will increase approx. 2 psi with Kenne Bell Cool Air Kit.

That clearly indicates the Eaton simply is maxed out and cannot pump sufficient air to

keep up with the engine. The lower revving less powerful Lightning is able to better

utilize a larger diameter crank pulley as "boost drop off" is not as severe as

the Cobra.

RPM Outlet sell a 2.93 and a 2.80 8 rib pulley for $90 US each - the pulley puller is also $90US - the cheapest one.

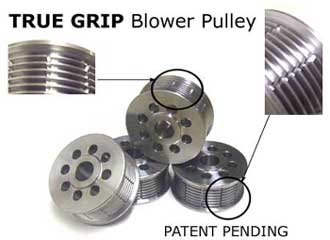

MOTOBLUE™TRUE GRIP Blower Pulleys Add Serious Horsepower Without Belt Slip

Well we did it again! We found a manufacture that likes doing thing the right way. MotoBlue! MotoBlue has developed a new lightweight steel blower pulley for the Eaton supercharger. Not only is it a good-looking piece but it does what no other pulley will do. It promotes belt traction. Best of all you don’t pay the high price other manufactures are trying to charge for the same technology.

Don’t be fooled by over-priced, cheap aluminum, and skimpy hub “quick change” upper pulley kits for your Supercharged Vehicle. We have shopped around and were surprised by what others are trying to pass off as a “quick-change” upper pulley kit. Did you know that you need a special pulley puller installation tool and a special adaptor tool, which is not included in their “quick-change” upper pulley kit? A “special” pulley puller tool is required to remove the stock pulley and install their low-grade aftermarket hub. Yes, we did say low grade. Why would anyone press on an undersized impossible to remove hub to a steel shaft? What are the odds that the hub will be irremovable and damage the blower shaft? You couldn’t place the bet.

Eliminate Belt slip with our New TRUE GRIP ™ Blower Pulley

Thrasher do a lot of V6 GM stuff - their modular pulley looks the same as the V6 Supercharged offering above. Sizes are 3.4" 3.25" 3.0" or 2.76". Pulleys are about $70US

http://www.thrashercharged.com/store_htm/pulley_group.shtm

Can I just use my

stock belt?

Yes you can for our 3.4 Modular and Press-On pulleys ... but you're really cutting

yourself short. We highly recommend Goodyear Gatorback® belt for added

traction and performance! We stock belts that custom fit all of our pulleys, whether you

choose our Press-On or Modular! Just specify the pulley size and style you want when

ordering and we'll pair it up with the correct belt.

$22 US

$22 US

Why take a chance on damaging your supercharger or warping

and disorting your pulleys? You've probably heard some of the horror stories. THRASHER

delivers. We over-engineered our tool to be the strongest, most reliable removal &

installation tool with absolutely zero failures.

We're the innovators that pioneered the process for removing and installing these

supercharger pulleys unharmed as soon as these cars came to market back in 1997 proving

they deserved true muscle car status!

ACCEPT NO IMITATIONS.

THRASHER is the industry standard.

$140

- $115US depending on sale price - can be rented from $35 US.

$140

- $115US depending on sale price - can be rented from $35 US.

Kick it up a notch! Want to run a more aggressive pulley but don't want to fork out big bucks for race gas? Our system grows with you, one pulley at a time.

The THRASHER Modular Pulley System allows 10 minute pulley

changes! The hub installs once using your THRASHER Pulley Tool. Pulley changes are a

snap - 6 bolts and you're done.

hub is $70US and the pulley is $70 US as well.

hub is $70US and the pulley is $70 US as well.

Our 100% CNC machined Aluminum THRASHER Modular Pulley is anodized black and engraved for that finishing touch of quality. Kick it up a notch ... one pulley at a time!

How far will you go with your ride?

Just how far can the THRASHER Modular Pulley System take you? As far as you desire! Call us and will help you decide what modifications you should make now and just how far you can go! Ok, so you'd like to have it all. If you want to "ease into" building your dream ride, THRASHER makes it easy. We developed the modular concept and set the Industry Standard others look to for these Supercharger Pulleys AND Pulley Removal Tool. Make no mistake, we've got the facts because we did our homework. This is where it all started.

THRASHER Engineered Performance pioneered the process for removing and

installing the supercharger press-on pulley unharmed as soon as these cars came to market!

That's right ... we had the guts to take on the challenge of removing the stock, press fit

pulley when others wouldn't dare! We perfected the technique and released our Pulley

Removal Tool and pulley to the public in January 1997. After extensive testing to ensure

ease of use and determination of the perfect sizes for the ideal balance between low end

torque and upper RPM horsepower ... all while using 92 octane pump gas*, we released our

product. Thorough testing is standard procedure for THRASHER. Our customers can rest

assured because we have a 0% failure rate. Accept no imitations! We are the industry

standard.

Our

Modular Pulley System is FLEXIBLE. After

removing the stock pulley with our Pulley Removal Tool, our steel hub presses on using

that same tool!

*THRASHER has determined that increasing boost

significantly beyond 11 psi on the Eaton M90 blower was detrimental to performance without

an intercooler.

You know what you want. If you are just wanting a to make a "one-time" change out and know exactly what you want, the THRASHER Press-On Pulley is an excellent choice. Machined from 100% virgin steel, you get high quality for a price that's hard to beat! (Recommended belts sold below.)

Press-On Pulleys available in these sizes:

3.4" 3.25" and 3.0"

Important! 3.0" & 2.76" require an intercooler!

ASP Pulley Puller http://www.southfloridapulleyhq.com/products_puller.htm

This is the newly updated improved version of the ASP pulley puller. As you can see by the picture above, the backing plate has been dramatically thickened to 3/4" for much more strength. Also improved, are thicker 5/8" washers, and a second one has been added for both sides now.

ASP Pulley Puller: $145 US plus $11 S/H

NOTE:

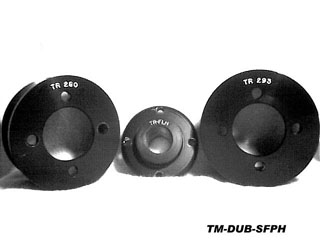

You DO NOT want to attempt to remove the Hub Assembly with the DUB Pulleys attached to it, as it will distort the SC Pulley as you attempt to remove it. You MUST use the Dial_Ur_Boost Hub Removal Backing Plate to safely and easily remove the DUB Hub. We sell the Backing Plate separately in our Products section.first innovate

South Florida Pulley

Headquarters proudly introduces the first innovated Interchangeable Supercharger Pulley

combination for all Eaton Model 112 Superchargers on your Ford Lightning!! It is

called "Dial_Ur_Boost"

This newly developed Supercharger Pulley combination consists of a High Quality Aircraft

Aluminum Anodized SC Pulley and Nitride Coated SC Steel Hub Assembly. This unit is

"The Absolute Replacement" for all press-on aftermarket supercharger pulleys and

SC snout units!

Once the "Dial_Ur_Boost" unit is installed onto your present SC snout shaft, you

can easily from then on, change your SC pulleys in less than 10 minutes, start to finish!

Using the ASP Pulley Puller Tool, which you can buy or rent from us, you will remove

your present press-on SC pulley. Once off, then simply press on our New SC Pulley

Steel Hub Assembly with the Pulley Puller Tool. Then you will be able to simply slip

the New SC Pulley of your choice onto the Hub Assembly and attach the 4 Allen head bolts

to secure your New SC Pulley!

The stock Supercharger Pulley produces about 9 lb. of boost, whereas the DUB 2.80" Performance Supercharger Pulley has shown 12 lb. of boost by many owners of this unit. Also from one of our Vendors, we have an update from the Track over the weekend. One of the modified 2001 Ford Lightning's running a 12.82 ET with a stock SC Pulley, upgraded to the DUB 2.80" Performance SC Pulley and ran a 12.53 ET. That was not only a 3 lb. increase in Boost pressure, but also nearly 3/10's off their quarter-mile ET!!! How's that for performance??

http://www.troyerperformance.com/

Supercharger (Upper) Pulley Removal Tool for Eaton M112 superchargers as found

in SVT Lightning, Harley, SVT Cobra, etc.  $149 US

$149 US

Correctly supports the rear surface of the supercharger pulley to ensure the pulley stays "square & true" on the shaft for easy press-off & press-on installation of higher boost upper Supercharger Overdrive Pulley.

Avoid the mess of having the supercharger pulley seize on the shaft from cocking and/or tilting of the pulley as happens when trying to use conventional 3-jaw puller tools, etc. That happens because the pulley is not properly supported on the majority of the rear surface, which then allows the pulley to tilt and/or cock, and potentially seize up on the shaft, requiring repair.

This is the very same tool we use ourselves here at Troyer Performance to install these pulleys!

Well perhaps a 3.0 inch pulley to make my M112 put out an estimated 9.12 psi would be a good starting point- perhaps the intercoolers will lower the temperature enough to stop detonation? For a second pulley? - maybe the 2.7" one? I like the Pulleyboys stuff - looks great. Make a tool or buy a tool? I'm tempted to get the modular pulley and just get it pressed on locally.

Blower pulley diameter (inches) |

M112 boost with my hot cams (18 degree overlap) |

3.8 |

4.39 |

3.7 |

4.87 |

3.6 |

5.37 |

3.5 |

5.91 |

3.4 |

6.48 |

3.3 |

7.08 |

3.2 |

7.72 |

3.1 |

8.40 |

3.0 |

9.12 |

2.9 |

5.46 |

2.8 |

10.73 |

2.7 |

11.62 |

2.6 |

12.59 |

2.5 |

13.62 |

2.4 |

14.75 |