I am reading a book called "21st Century Performance" by Julian Edgar at the

moment.

You can buy it from www.autospeed.com.

Anyway there are two particular chapters with very interesting information on the

1UZ-FE V8.

The first chapter "Engine and Driveline" part "camshafts" has a whole

section about the 1UZ-FE camshafts and how they compare to other high performance engines.

Standard specs are listed and they model changes (using Dyno2000 software) to the cams and

resulting horsepower increases.

The most effective would seem to be changing the standard exhaust cam for an exhaust cam

with revised opening of 55 degrees BBDC (Before Bottom Dead Centre) and closing of 18 ATDC

(After Top Dead Centre) (standard exhaust is 46 BBDC and 3 ATDC). This changed exhaust cam

with the standard intake increased the horsepower from 260 to 300 !! (modelled on

Dyno2000).

The second very interesting bit is head porting. A 1UZ-FE head is flow benched before and

afterward being ported. Increases in flow on the bench usually relate directly to

horsepower increases. After porting the intake flow increased by 19 percent and the

exhaust by 14 percent!!! These are actual flow bench figures. Not only that but there are

12 full colour photos of before and after close ups of all the critical parts to pay

attention to when porting.

But back to the camshafts. I have read many times that Ivan Tighe has done camshafts

for lots of special cars and custom applications.

IVAN TIGHE ENGINEERING PTY LTD

Camshaft Grinders

223 Montague Rd West End 4101

Queensland

Australia

(07) 3844 4283

(07) 3844 8505

mobile 0419 774 441

His name gets mentioned for all the tricky stuff including the Perth Car and the

Queensland Bullet Supercharged car.

So I rang and spoke to Dean Tighe about the cams. They have done about 10 pairs already

for drag cars, speed boats, supercharged cars etc.

He agreed that the doing the exhaust cam first was a reasonable step.

If he receives the old cams he welds them and grinds them to the new spec. Takes about a

week (or three) and costs about $450 (for an extra 40 hp - this is a computer simulation

only so far).

If it does work it is an excellent hp for dollar ratio.

Hardfacing the cams is not the same as a straight regrind. The lobes are welded and

built up before grinding (NB. hardfacing electrodes such as UTP electrode DUR 600,

Soudokay 600-O and CIG Cobolarc electrodes welds a hard-face overlay to the existing lobe

of the camshaft using the most advanced alloys -this has proven extremely durable. If you

want too much info on hardfacing then you want the hardfacing.pdf from http://www.cigweld.com.au/pages/images/techinfo/consumtech/hardface.pdf

(341kB). Lots of information including diagrams etc.). You would only expect the cams to

last about 60 000 km before they start to pit and wear. Not nearly as good as original

cams.

However if the cams work and prove themselves on the dyno then he make some brand new ones

that will last forever and match the OEM quality. We are looking at about $1200 for a

pair. Since my engine has an annoying tap tap and needs the valves shimmed anyway, it

would be a perfect opportunity to whip out the exhaust cams and send them off. I may have

to re-shim all the exhaust valves to suit the ground cam (not too much hopefully).

Long term Dean suggested doing the intake cams as well would be something to look at.

The helical centre drive gear comes off and can be reused on the new cams no problem.

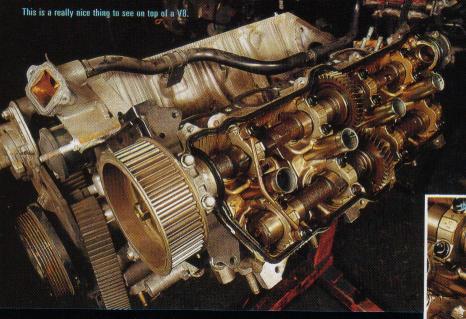

Figure 1 Intake cam is belt driven, exhaust cam is split helical gear drive off intake cam

Only the intake cam is connected to the drive belt - the exhaust cam comes out so much easier than the intake cam. Getting the timing marks lined up when reinstalling is the critical thing.

Figure 2 Sample Computer model of intake cam change

21st Century Performance details models of several scenarios - the best one for a

street car was changing the exhaust cams only. This gave the green line in the graph

above. Since my engine had some valve shim noise, you could hear it tap tap tapping, I was

pretty keen to re-shim the valves so it was a good opportunity to whip cams out and send

them off to Dean Tighe. So that is where they are now.

I have dyno runs for my car before the exhaust cam change and I will do another afterwards. Since three intake valves needed shimming, the dyno will reflect this change as well. The goal is to get something like the green line.

next will be 2. 1UZ-FE V8 Camshafts - In Practice and 3.

1UZ-FE V8 Camshafts - Results.