|

Changing the diff for a TORSEN |

by Peter Scott

My first oil change for my open wheel rear differential (diff) was way back at 76 000 km (48 000 miles), that was September 2001 - man time flies! The magnet on the drain plug showed the diff was in good health and all was well. I changed the oil with standard specification mineral oil, hypoid 90W/80.

I wasn't going to crawl under the car with just the jack from the boot holding the car up - ooh no - I chocked the front wheels with some bricks and used some sturdy stands. The sump plug was real tight. A 10mm hex drive or allen key is needed.

I cracked open the fill plug first of all - I needed a big breaker bar on the allen key to get enough leverage. I used the biggest ring spanner I had and hooked it over the end of the allen key - I couldn't find a sturdy piece of pipe - the allen key by itself didn't get me enough leverage to crack it open. Once that is open I removed the drain plug and out poured in 1.3 litters roughly of stinky diff oil. In the background is my super sexy new Supra TORSEN diff - more about that in a minute.

To get the oil back in isn't too hard - I had one of those small cheap oil pumps from an autoparts store and the Castrol bottles came with a built in plastic tube - handy to fill up the diff. Once the oil started to overflow from the fill plug I was done. Since you are an enthusiast, get the good synthetic diff oil, and 80W gear oil is fine, I prefer Castrol SAF-XA - I use two 1 litre bottles.

Hopefully your sump plug will be healthy and covered in metallic

dust - texture of fine clay - on the left. On the right is the clean plug - the magnet now

clearly visible. Engines have filters and non-metallic bearings - no use for a magnet

there.

This time in amongst the "dust" I found these chips of metal. Oh oh - this is a bad thing! That red thing is a match stick head for reference. These are more than likely broken bits of the sun gears. My diff still worked ok - nice and quiet - I would never have suspected anything was wrong.

I don't know of very many V8 diffs that have failed. My mate Juzza's diff ground to a halt at 200 000 km and Neil's diff had had enough at 300 000km. Both cars have been on the circuit.

So time to find another diff. I had always planned to upgrade to a TORSEN (Torque

Sensing) diff and getting a higher ratio could only help get my Soarer

off the line quicker. So I went shopping for one.

Local wrecker All Jap Adelaide had on in stock to suit for $1200 - a torsen diff

with slightly higher ratio.

Kristian Hancock in Melb had one for $800 or just the Torsen centre to fit for $700.

Japanese motorsport in Adelaide might have had one - they were still looking

after a day and 2 phonecalls - they quoted me $900 drive-in, drive out (fitted and

changeover) - so that was looking good too - If they had one.

Japanese Auto Mart had had one in the showroom floor for over 2 months apparently - 1994 Toyota NA Supra auto - The Twin Turbo Supra diff is too big and wont fit. The non-turbo Supra diff was a TORSEN (diff code A02B on engine bay plate) and would fit the Soarer. Another bonus is that it has extra cooling fins cast into the whole casing unlike the Soarer TORSEN option. TORSEN diffs make more heat than regular open wheel diffs.

Well I'm no expert but there were a few obvious traits - stock Toyota diffs are TORSEN

or open wheel - sometimes a diff might be changed internally with a mechanical action

diff. TRD or CUSCO etc - When Juzza got his diff he scored one of these diffs by accident,

on sharp slow turns the inside wheel chirps and squeals a little bit as it tries to keep

up with the outside wheel - a TORSEN diff is super smooth. Anyway on the wrecker showroom

floor the TORSEN diff has differences to an open wheel diff. With a TORSEN LSD on a

workshop floor there are a couple of tests to do.

First is the spin one axle and the other axle spins same way - Torsen. If the other axle

spins other way then go to test 2.

Test 2

Spin the input shaft of the diff. One wheel will may spin freely with the other

stationary. I can hold one axle still, spin input shaft and the other axle will spin free.

If I try to stop the spinning axle with my leg, just let the spinning axle rub my calf for

example - the axle I am holding still with my hand will instantly start spinning in same

direction. As soon as any torque is applied to the spinning axle - torque is transferred

to the stationary axle and they spin together. TORque SENsing.

A metical clutch type LSD or cone type LSD tends to spin both wheels in same direction the

whole time to a degree. There isn't so much "free wheeling" as available in a

TORSEN.

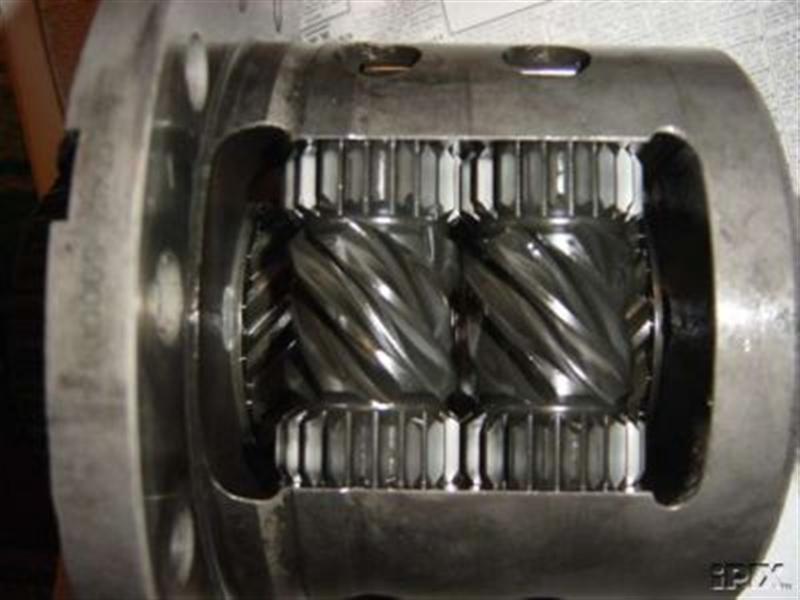

A TORSEN diff (also called a Quaife diff in Audi and BMW) transfers torque extremely fast.

Imagine a pizza size tray big cog connected to a small thimble sized small cog, and

imagine the gears cut at an angle in a worm arrangement rather than straight cut. The

thimble will easily drive the pizza tray - free wheeling situation. But try to get the

pizza tray to drive the thimble

and the whole lot locks solid - no movement. This is the torque sensing mode - well sort

of - that's a simple explanation.

And contrary to popular opinion, fitting a TORSEN does not suddenly mean the car is

dangerous or tends to flip out sideways. I got more sideways action with an open spinner.

Now I get drive where as before I got slide.

The friction of a tyre is maximum just before it slips. A spinning tyre provides very

little friction compared to a none-spinning wheel.

A tyre has to provide enough friction to stop car going sideways and move the car forward.

There is only so much force it can put to the road - all forwards, half forwards half

turning, all turning etc.

By spinning the inside wheel in my open diff I effectively made it useless for anything -

it didn't make the car go forwards, it didn't make the car stop sliding sidewards.

Now it was all up to the outside tyre. Since it was pretty much maxed out using all it's

available force to make the car go forwards, it had none left for stopping the car go

sideways and sideways the car would go.

Effectively with one spinning tyre - I only had one over stressed tyre to stop back end

going sideways.

With my TORSEN I don't have spinning wheels - both tyres stay put and pull their weight. I

have two tyres providing driving force and two tyres stopping the car going sideways -

much better. The car is much more planted and much more stable - most noticeable in the

wet - it doesn't budge.

BUT

yes If I really belt it in a U-turn and break traction in both wheels then it will over

steer - but I have to push it real hard to do that.

I have far more confidence in the car now - it handles much better. Fitting a TORSEN diff

from a Supra (auto mid 90's) was one of the best upgrades I've done to my Soarer.

I don't know what the torque ratio is for my diff. In practice this means that you can spin one wheel with a TORSEN diff if it is in the air (you can't with a clutch type LSD), but as soon as the spinning wheel gets any traction at all, or if the brakes are applied (handbrake or footbrake or Japanese spec traction control) the stationary wheel gets torque as well. A further description of the TORSEN diff is at the end of the page.

I found the diff using the yellow pages after searching

partslocator.com.au - I rang around 8 local wreckers to find one.

OK so I had found a diff - next was oil - capacity as usual is just a bit more than one

new bottle at approx. 1.2 litres. I had read that TORSEN diffs get hotter and really need

a synthetic oil - especially with a bit of circuit sprinting thrown in.

Redline 75W/90 gets rave reviews at $27.85 for 945ml - so two bottles needed for total of

$55.70 - holy cow! (80W mineral diff oil starts at around $5 for 500ml). Redline is

a top quality oil and available in South Australia from:

Pfitzner Performance Gearbox

ABN: 68 095 283 686

E-mail: ppg@gearbox-racing.com

Address: 14a Watervale Drive

Green Fields

South Australia

5107

Telephone: +61 8 8285 2933

Facsimile: +61 8 8285 2944

http://www.gearbox-racing.com/index.html

Looks like a top quality outfit who do race gearboxes - they have full range of redline

oil in stock

http://www.redlineoil.com/

The other full synthetic oil I am aware of is Castrol SAF-XA.

Also gets rave reviews, costs $26 for 1 litre and is available just about everywhere.

http://www.castrol.com.au/products/pdf/B912%20SAF-XA%20.pdf

Used at LeMans etc, extreme race fluid blah blah etc.

And my Brother Andrew stocks it at Motormate - well that will do me!

Now I wonder if my diff would have lasted longer with synthetic fluid or if it's time was

up anyway. Regardless from now on it's Castrol synthetic oil for me.

Anything more fun than lying on you back outside in the dark with dirt falling in your eyes and not having the right tools to do the job? I got the exhaust off ok, the tailshaft and the cross bracket a piece of cake - the six 10mm allen key bolts that hold on the axles where tight but manageable - they cracked open just like the diff plugs with a breaker bar on the allen key. The 4WS rear rack on my model was a real pain. I could remove the three bolts that held the rack and move it enough to see that I needed a 12 mm allen key to remove the rear three bolts to the diff. Who has a 12 mm allen key? So no more working that night.

Next day on the phone trying to find a 12mm allen key on a Saturday morning - no luck anywhere, then I located a 12mm HEX socket that would fit at Motor Traders across town. Got that home and that night there was no way it was going to fit unless the rear steering rack was removed. But the rack was held by two steering cables, two hydraulic lines and some electrical plugs - I wasn't ready to pull off all that and hope for the best - time to find a standard allen key instead of the socket. But these were extra hard to find - finally found 1 of two in Adelaide and got that on a Sunday morning at The Tool Man ($12). Still no way was I going to get enough room unless I removed the tie-rod ends first.

Nothing I had was going touch the tie rod ends - they were jammed solid. Arrgghhhh! So back to Tool Man again for a Tie-rod end lifter (that's it on the right) at $32 bucks. Finally I could wiggle the steering rack enough to get to the rear diff bolts. Then a bent a 22mm Metrinch ring spanner I hooked on the end of the allen key trying to undo the bolts - they were rock solid. Used a big sold piece of pipe to put over the allen key to try to break the bolts open - the bar was so long and the car not quite high enough so trying to find just the right angle and get everything lined up just so was another pain - sometimes you just want a hoist so bad! So on the third day the diff was finally ready to lower (not three solid days! - I did have other things on). The is so heavy I had to use the jack to lower it.

BUT

One of the axles was jammed on solid, locking the tailshaft and the other axle and then using a long breaker bar on the wheel stud threatened complete wheel stud destruction. Excellent! So back in with the diff, back on with the loose axle and it's bolts, a complete re-installation of everything except for the bolts on the tight axle. Then I started the car, did 20 km/hr on jacks and applied the brakes to pop the axle off finally! So at the end of day three all I had was no exhaust, a loose axle and a wobbly steering rack with original diff firmly attached in place. Day four was raining - spent all day clearing a space inside the shed and finally lowering the old diff - so only took 4 days to get the diff out! - ha! - great! :( Of course publicly I just say 45 mins for the diff and 15 minutes extra for the steering rack - no one will ever know otherwise......

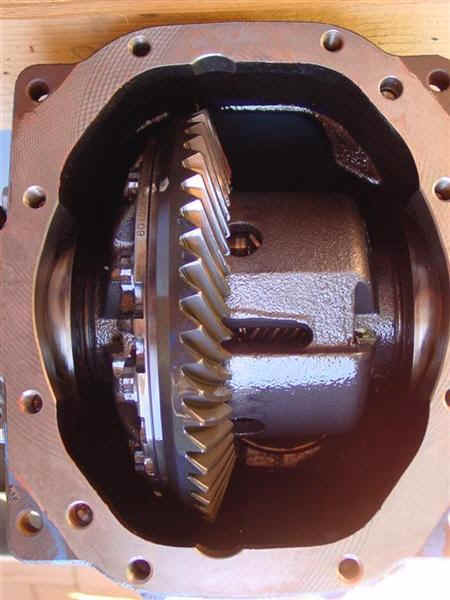

Ha yes the sexy TORSEN Supra diff with big cast cooling fins top and bottom. Shorter gearing will get the car launching a bit better. Notice how my tools look a bit hap - hazard, started off neat enough but things changed as night turned into day, several times, and it rained as well. This diff is from a NA MKIV Supra with 4.083. The standard Soarer V8 diff is about 3.9

Check out those bottom fins! Should be good for dumping heat on the circuit - synthetic oil to cope with the heat will help. Yes I know it looks a bit messy with the oil dripping from the fill plug - but I did give it a wipe afterwards promise.

Top view of both diffs.

Driving the car with the new diff not a lot is noticeable at first - still smooth and

quiet. Perhaps it is a bit more punchier off the line - but I would really need a

stopwatch to notice. Biggest difference is the car is now an oversteerer when provoked

with the throttle and Traction Control is off. With TRC and Active suspension my car is

real hard to get out of shape. Turn TRC off and corner too hard and hit the throttle hard

and the car oversteers a lot as both rear wheels spin. It is a lot different to before -

it swings out harder and further than with the open wheel diff. Before the car would just

light up the inside wheel and track around reasonably straight. With TRC on and the open

wheel diff and racing tyres the TRC would brake the spinning wheel giving more drive to

the wheel with grip - sort of a pseudo limited slip - on the circuit I would leave TRC on,

cuts down on tyre bills and gives me more drive. With the TORSEN and TRC off even simple

full throttle U-turns need a completely different attitude at the wheel, now the car steps

out further and comes back harder, different wheel work is needed to control the car than

before.

In the wet it's fantastic - a lot more stable. With the old diff, once you got one wheel spinning, that wheel lost all traction - frontwards and sideways. This meant the other wheel had to cope with all the sideways forces. Since it was already at the limit providing thrust, there was not enough frictional force to stop the car going sideways. With the open wheel diff and one wheel spinning the car snaked sideways more than with the Torsen diff.

In the wet or the dry the car has more drive out of corners and in a straight line - and it's more stable - especially in the wet. I always imagined two wheels spinning would make it uncontrollable, but in fact the TORSEN prevents spinning in the first place - I really like the it.

A good write up on the TORSEN diff and pictures is in the Supra MKIV New Zealand site:

click here: TORSEN diff

Torsen and Quaife diff's can have a multiplication factor of up to 6x, but it is said that somewhere down the line steering will be affected. The Quaife is a modification of the Torsen, it has an additional friction element inside, so that even the airborn situation is tackled; and if it wears out, you still have an ordinary Torsen.

Torsen I - Z30 Soarer, early A80 Supra - if one wheel is in the air then it will spin freely. Handbrake will transfer torque to wheel with grip.

Torsen II - late A80 Supra, Z40 Soarer - has bias plate in middle torque delivered to both wheels even if one is in the air. May cause chatter during slow tight turns.

http://www.trackdaymedia.com/~manny/Tech%20&%20Diag/Torsen%20Performance%20Technical%20Sheet.pdf

http://www.trackdaymedia.com/~manny/Tech%20&%20Diag/Torsen%20LSD%20-%20Traction%20Control%20Article.pdf

http://www.trackdaymedia.com/~manny/Tech%20&%20Diag/Torsen%2520T-1%2520Technical%2520Sheet.pdf

http://www.trackdaymedia.com/~manny/Tech%20&%20Diag/Torsen%2520T-2%2520Technical%2520Sheet.pdf